Overview

Lowering the cost of electric vehicle (EV) batteries is one of the most important factors for making electric vehicles more affordable for consumers. Batteries are the most expensive element in virtually all electric vehicles and the high cost of batteries is often cited as a critical barrier to widespread adoption of EVs.

If the initial manufacturing cost of batteries can be reduced and battery lifecycles extended, it will help to increase the growth in market share for electric vehicles, which ultimately will have a significant impact on reducing greenhouse gas emissions and improving air quality.

This article provides a deeper dive into the importance of Battery Interconnect System technologies that are helping reduce EV battery costs by simplifying design and assembly while at the same time extending battery lifecycles by improving current flow and minimizing hot spots within EV batteries.

Why are Battery Interconnects Important?

There is no doubt that the rapidly growing adoption of EVs along with the need to charge them will have impacts on the electrical grid. However, there has been a fairly diverse range of opinion about how those impacts will play out.

Battery interconnects are an essential component of battery packs in electric vehicles. They serve as a critical linkage between the individual cells within battery packs and also for connections to external circuits by aggregating and conducting electrical current from the battery cells to the terminals of the battery pack.

Battery interconnects typically consist of a set of current collectors, which are most often made of copper or aluminum, and are bonded to the electrodes of the battery cells. They provide a low-resistance pathway for the flow of electrical current from the battery cells to the external circuit.

Current collectors also help to distribute the electrical current uniformly across the battery cells, thereby improving the overall performance and longevity of the battery pack.

The use of battery interconnects is crucial for reducing costs and improving the lifecycle reliability of EV batteries. By providing a low-resistance pathway for electrical current, battery interconnects help to reduce the energy losses that could otherwise occur within the battery pack, which in turn reduces the amount of heat generated by the pack. This can help to extend the lifespan of the battery pack by reducing the stress on the individual battery cells.

In addition, the use of battery interconnects can help to simplify the manufacturing process of battery packs by reducing the number of interconnects required between the battery cells and the external circuit. This can help to reduce the overall cost of manufacturing battery packs and make them more affordable for consumers.

Key Challenges for Battery Interconnect Optimization

When considering the impact of EVs, it is important to take a broad and long view for context on changes that are already underway in the grid. The key factors include expanded investment in capacity, transmission networks and renewable energy sources.

Accommodating Larger Battery Modules with More Individual Cells

One of the primary challenges facing battery designers and battery interconnect manufacturers is the trend toward grouping together more cells within each module and within the overall battery pack. With more cells needing to be connected, battery interconnects must maintain high-precision connections to all cells over larger physical form factors. This requires battery interconnect system manufacturers to deploy the highest levels of manufacturing precision and quality control for creating battery interconnect designs that cover more area.

Reducing Weight of Battery Packs

From the beginning of the mobility revolution, auto makers and suppliers have been challenged by the need to reduce overall vehicle weight and EV batteries have always been the heaviest component in the vehicle. As a result, battery interconnect designers are faced with requirements to make current collectors thinner and lighter even as they are also tasked with increasing the surface area to connect more cells.

Avoiding Hot Spots

Current collector hot spots are localized areas of high temperature that can occur in battery interconnect systems in EV battery packs. These hot spots are typically caused by uneven current distribution within the current collector, which can lead to localized heating and thermal runaway.

Cell Balancing

Cell balancing is a process of trying to make sure that each cell is charged and discharged equally, so that the battery pack operates as efficiently and safely as possible. When the cells in a battery pack are not balanced, some cells may become overcharged or undercharged, which can lead to reduced performance, reduced lifespan, and in extreme cases, safety hazards such as overheating or fires.

Using a battery management system (BMS) can help by monitoring temperatures and adjusting the charging and discharging rates or the BMS can issue alarms and shut down the battery if necessary. Adding insulation or cooling can help too but increases both cost and complexity. Ultimately, the best way to deal with hot spots and lack of cell balancing is to design current collector assemblies for optimal current distribution throughout the battery.

How Cell-PLX™ with U-Turn Technology Optimizes Battery Interconnect Systems

Successfully addressing all these challenges simultaneously has required a radical new technology approach, with a comprehensive battery interconnect system.

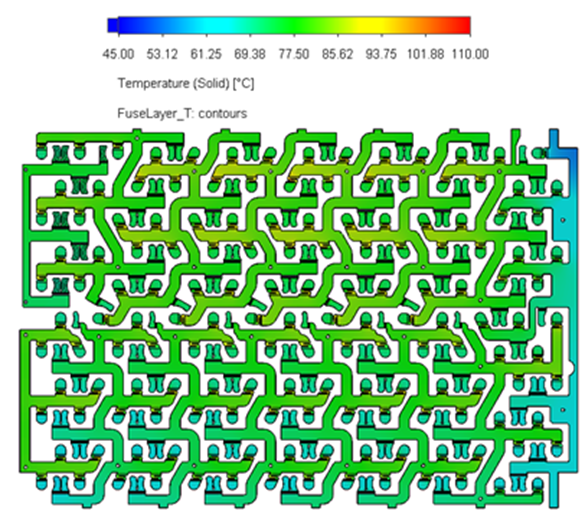

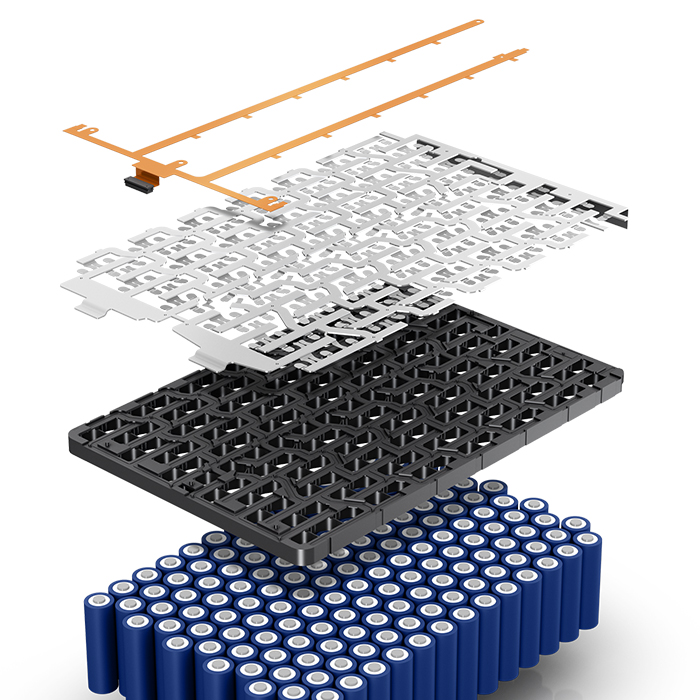

The Cell-PLX™ advanced customizable battery interconnect system from ENNOVI is a lightweight, ultra-flat, robust current collector approach that helps EV makers overcome the challenges of customizing reliable battery connections.

Using customizable attachment processes to support specific application requirements, Cell-PLX™ battery interconnect systems are designed to provide a permanent, reliable, robust, and safe solution for current collectors to interconnect EV battery cells and provide electric power to the vehicle.

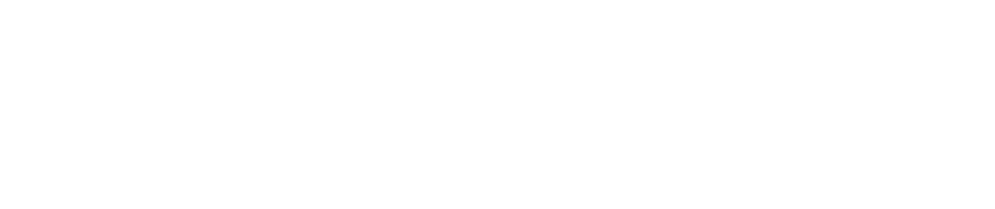

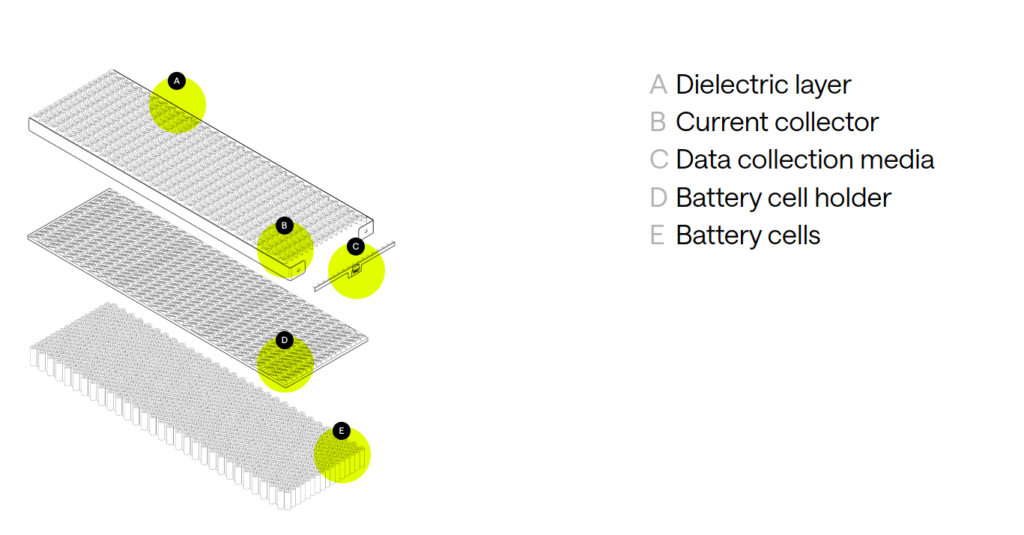

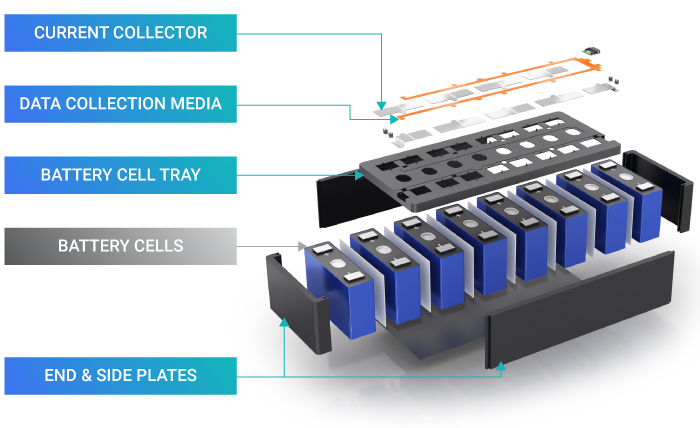

During the battery interconnect assembly process, the current collector with a dielectric layer, data collection media which consists of the flex printed circuit (FPC), battery cell holder and individual cells are all brought together in a highly efficient and robust manner that supports high-volume manufacturing and can be adapted for virtually any battery pack size, power requirements and configuration.

Flatter and Thinner Current Collectors

By leveraging precision engineering and manufacturing, ENNOVI can provide customers with virtually any size and configuration of current collectors while also making them thinner and flatter than any previous processes could achieve. In addition, the thickness of the current collectors can be altered in the required areas, for example, less material in the cell tabs, and more material in the main current paths. Because it is thinner, with a layer being saved, more space is left for energy storage. Furthermore, using less metal conductor material means there is less heat that needs to be dissipated.

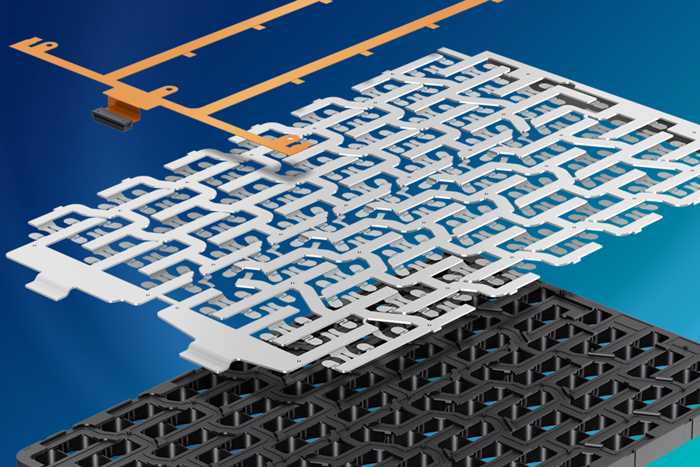

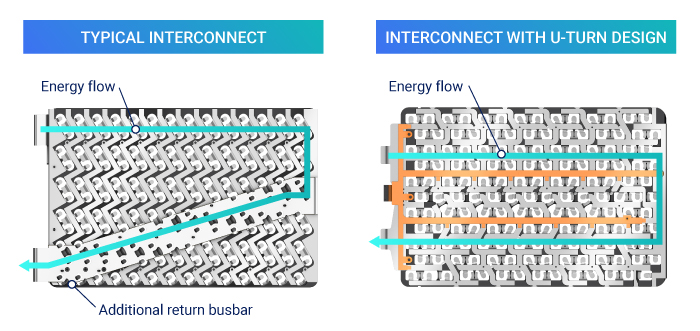

Minimizing Hot Spots with U-Turn

With the introduction of new patented U-Turn design option, ENNOVI has now further expanded the Cell-PLX™ technology to address another key issue, which is the tendency for EV batteries to develop hot spots within the current flows across current collectors. The U-Turn technology enables a much more uniform distribution of current throughout the battery interconnect thereby preventing hot spots without requiring complex and expensive add-on mechanisms for monitoring or mitigating hot spots after they arise.

Here again, ENNOVI’s precision, high-volume manufacturing methods and quality control measures ensure each Cell-PLX™’s current collector has a consistent thickness, even for very large battery interconnects, which helps achieve this evenly distributed power spread with U-Turn across the whole battery interconnect system.

Key benefits of U-Turn design technology:

- Provides even spread of current throughout the battery.

- Eliminates current bottlenecks that cause temperature spikes.

- Distributes uniform current density across the battery.

- Elimination of hot spots prevents degradation of battery life.

Keen to understand how our Cell-PLX™ core technology can be applied to your battery applications?

Summary

The improvements in Battery Interconnect System technology described above have many benefits, including the following:

- Lowering the cost of EV batteries will make EVs more affordable and accessible to a wider range of consumers, accelerating the transition to a more sustainable and low-carbon transportation system.

- Longer-lasting batteries can help to improve the performance and range of EVs, making them more competitive with traditional gasoline-powered vehicles and increasing consumer confidence in EVs.

- As the adoption of EVs increases, the environmental impact of transportation will decrease, reducing greenhouse gas emissions, air pollution, and reliance on fossil fuels.

- The same battery technology used in EVs can also be used for energy storage systems, such as grid-scale batteries or residential energy storage systems. If the cost of batteries can be reduced, it could help to accelerate the deployment of energy storage systems, which are essential for integrating more renewable energy sources into the grid and improving grid stability.

- The high cost of EV batteries is often cited as a major factor contributing to the low profitability of EV manufacturers. If the cost of batteries can be reduced, it could help to increase the profit margins of EV manufacturers, which would in turn lead to more investment in research and development, and ultimately lead to more affordable and better-performing EVs.

- Enhanced battery designs can also lead to improvements in battery recycling, as a larger portion of batteries can be reused or repurposed, reducing waste and promoting a circular economy.

In summary, lower cost EV batteries with longer lifespans can have wide-ranging benefits for both EV makers and the world at large, including increased adoption of EVs, improved performance and range, reduced environmental impact, increased energy storage capacity, cost savings, and improved battery recycling.